Peshing Technology White Paper

The novel properties of HEA, such as super specific strength, excellent mechanical properties at high temperature, excellent toughness and fracture strength at low temperature, super magnetism and superconductivity, are used for different series of HEA products in aerospace, Paving the way for applications in transportation, energy, electronics, biomedical, tooling, precision shearing tools and more. HEA products can be used as hydrogen storage materials, radiation protection materials, electronic diffusion barriers, precision shearing, electromagnetic shielding materials, thermal spray materials, hard low friction coefficient and biological coatings, adhesives, soft magnetic and hot spot materials, etc. .

Research status of high-entropy alloy powder printing

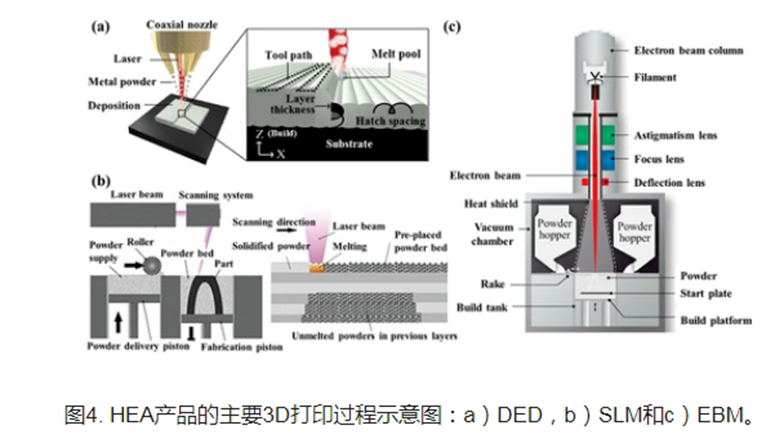

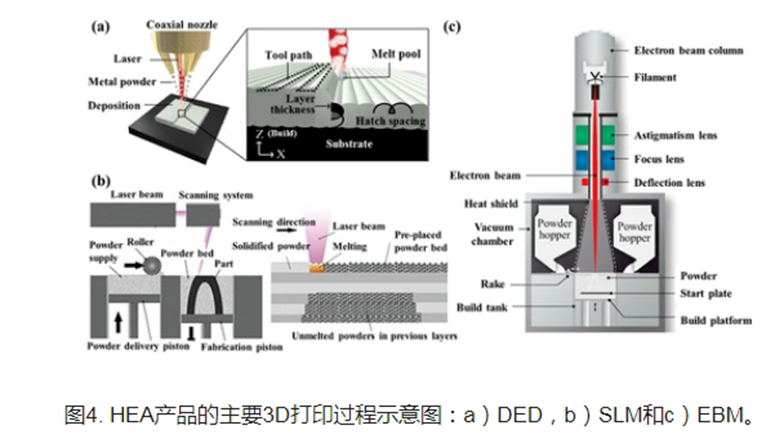

Typical 3D printed products of high-entropy alloys (HEAs), namely direct energy deposition (DED) and selective powder melting (SLM, EBM), are based on phase composition, crystal structure characteristics, mechanical properties, functions, and potential applications, especially It is used in aviation, energy, mould and tool industries.

Compared with traditional manufacturing processes, DED and electron beam powder bed melting (PBF) hold greater promise for developing high-entropy alloy HEA products. Focused high-energy beams in DED and PBF melt the powder into an almost dense product. At the same time, the ultrafast cooling rates of DED and PBF help prevent the formation of unwanted intermetallic compounds and diffusion of constituent elements, and lead to microstructural refinement of HEA products. However, rapid curing can lead to large temperature gradients that can create residual stresses and cracks in the printed product. Therefore, the constituent elements that are insensitive to cracks and strong enough to offset residual stress can be mainly considered for the composition design of HEA powders to improve their printability. Both DED and PBF can utilize HEA pre-alloyed powders developed by gas atomization, water atomizat.

During these processes, the focused high-energy beam interacts with the powder to form a molten pool where rapid melting and solidification occurs. Fast curing is beneficial to avoid elemental segregation that normally occurs at linear defects (more precisely dislocations) or surface defects (stacking faults, grain boundaries, phase boundaries, etc.) and prevent the formation of brittle intermetallic compounds, thereby improving the mechanical properties of the product.

Additional elements added to an existing HEA may refine its microstructure and promote the formation of precipitates and achieve a strengthening effect; as for the process state, optimizing the energy density results in an increase in relative density, a change in the orientation of grains , reduction in grain size and improvement in mechanical properties of printed HEA products. In addition, heat treatment is often used to improve the mechanical properties of HEA products by removing various defects and relieving residual stresses during DED and SLM printing of HEA products. Annealing can also effectively promote recrystallization and reduce residual stress.

Heat treatment can also cause problems with coarse grains in printed HEA products. The effects of grain coarsening and the release of tensile residual stress on the tensile stress of HEA products are interactive and relatively complex. Hot isostatic pressing (HIP) techniques can be used to densify the HEA product and to coarsen grains and precipitates. , When HIP processes HEA printed products, the coarse particles formed by the grain boundaries at the grain boundaries will cause the loss of its plasticity.

HEA products are reported to exhibit better corrosion properties than conventional alloys. The concentration and distribution of corrosion-resistant elements, phase transformation, and segregation of elements determine the corrosion performance of HEA products.

HEA products containing Co, Fe and Ni elements generally have electromagnetic wave absorption and magnetic properties. The coupling of composition and microstructure of 3D printed HEA products can significantly affect their magnetic behavior and magnetic properties. The magnetic saturation of HEA products is strongly dependent on composition rather than microstructure.

HEA products can also be used as hydrogen storage materials because of its high hydrogen storage capacity, high absorption and release capacity, and low cost of use. But further research is still necessary to reveal the mechanism of its formation and action.

Problems existing in high-entropy alloy powder printing

DED is the most popular technique for printing HEA products, using HEA powders to mix untapped elemental powders. The lower scan rate in the DED process results in a low cooling rate, which results in a relatively large grain size. relatively low strength.

The huge temperature gradient during the printing process is due to the high local heat input and short interaction time. Rapid heating and rapid cooling of the product can lead to higher residual stresses in DED and SLM processes, which can induce cracks. Different defects and internal residual stresses, which affect the microstructure, control the macroscopic product properties.

The microstructure of a 3D printed product is strongly dependent on its composition and process parameters. Despite the ultrafast cooling rate of the 3D printing process, the presence of undesirably brittle intermetallics was observed in the solutionized substrate. Therefore, heat treatments such as annealing, solution treatment and hot isostatic pressing are often used to avoid the formation of unfavorable precipitates, but cause coarse grains. HEA powder for 3D printing can be achieved by optimizing the powder process, in addition to common elements, noble metal elements (Ag, Au, Pd, Pt, Rh, Ru, etc.), low-density elements (Be, Li, Mg, Sc, Si, Sn, Zn, etc.) and lanthanides (Dy, Gd, Lu, Tb, Tm, etc.) can be used to consider the composition design of novel HEA powders. In particular, the elements of the composition should meet sufficient strength to resist residual stress and cracks during printing.

Due to the performance characteristics of high-entropy alloys, the surface shape of the printed parts is rough, which brings difficulties to subsequent machining.

references:

1 Top Issue AM Review: Research Progress of 3D Printing High-Entropy Alloys (3), Jiangsu Laser Industry Technology Innovation Strategic Alliance. It is reported that this article is the third part of the review of the top issue of Advanced Materials, which mainly introduces the performance and prospect of 3D printed HEA products.

2 Top Issue AM Review: Research Progress of 3D Printing High-Entropy Alloys (1), Jiangsu Laser Alliance.

3 3D printing high-entropy alloys-iron-based amorphous alloy composites, Shi Jie, Huazhong University of Science and Technology.

4 Top Issue AM Review: Research Progress of 3D Printing High-Entropy Alloys (2), Jiangsu Laser Industry Innovation Alliance.

CH

CH