Peshing Technology White Paper

Peshing has conducted continuous research on the application of laser melting of titanium alloys to ensure the stability of material properties and application results.

Among titanium alloys, Ti-6Al-4V (TC4) alloy materials are the most mature in application. TC4 titanium alloy is a typical α+β two-phase alloy, and its composition contains 6% stable α-phase element Al and 4% stable β-phase element. V, taking into account the advantages of α-phase and β-phase. Because of its low density, excellent heat and corrosion resistance, and high specific strength, it has been widely used in aerospace, biomedical and other fields. Selective Laser Melting (SLM), as an additive manufacturing technology, can realize the material-structure integrated net shape of complex structural metal components, which provides a new way for the design and manufacture of aerospace and biomedical high-performance components. process.

Peshing TC4 Powder Properties

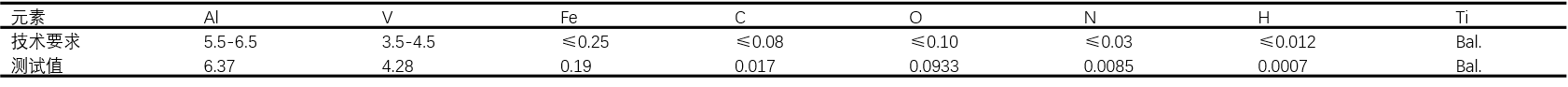

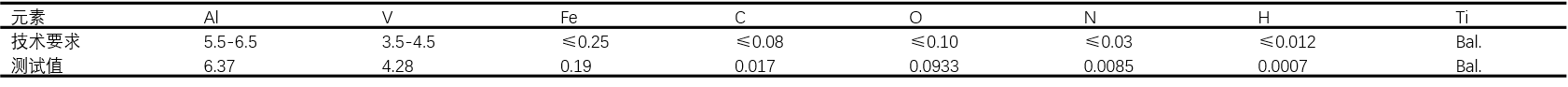

Peshing TC4 powder is prepared by electrode induction melting gas atomization EIGA technology. The composition requirements and test values of TC4 powder are shown in Table 1.

Table 1 Chemical composition of TC4 powder

During the milling process, continuous, stable and efficient production is achieved by controlling key parameters. After the powder is collected, 15-53 μm TC4 powder is prepared by sieving, air classification, batch processing and other procedures. The particle size distribution of 15-53 μm powder is shown in Table 2 below, and the particle size distribution of the powder is normal distribution, which meets the technical requirements.

Table 2 TC4 (15-53μm) particle size distribution

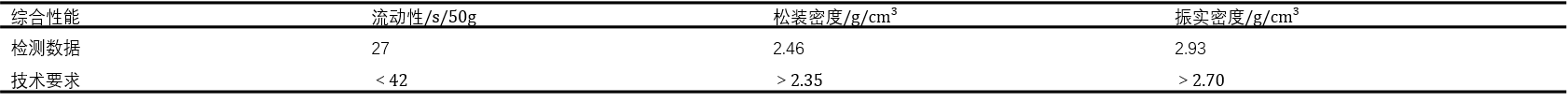

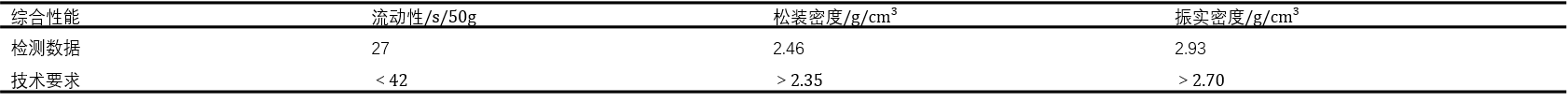

TC4 powder has excellent comprehensive properties, good fluidity, high bulk density and high tap density, see Table 3.

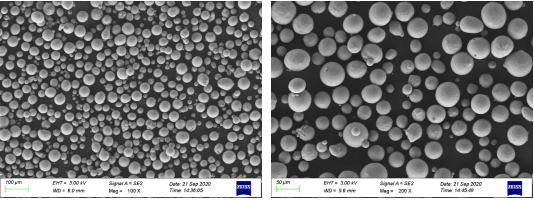

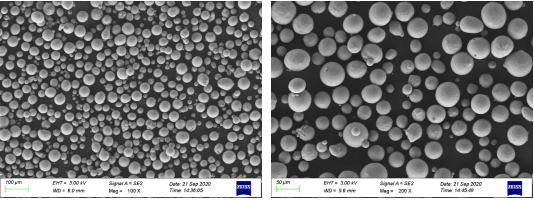

After air classification treatment, 0-53μm powder removes 0-20μm fine powder, the adhesion of the powder due to physical adsorption and the satellite powder formed in the atomization process are improved, the powder has good sphericity, and the surface of spherical powder is improved. The deformation is small, see Figure 1.

Table 3 Comprehensive properties of TC4 (15-53μm) powder

Fig.1 Powder morphology of TC4 (15-53μm) (×100, ×200)

Peshing TC4 Powder Selective Laser Printing

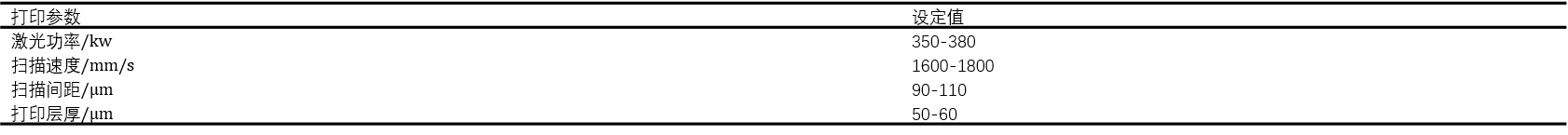

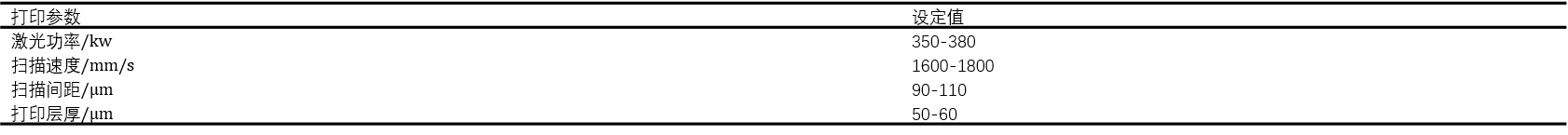

The TC4 standard sample was printed by a GE Concept Laser M2 printer. The protective gas was high-purity argon, and it was basically preheated to 200 °C before forming. The parameter settings are shown in Table 4. The heat treatment of the TC4 standard sample was completed by NB 380M vacuum heat treatment furnace.

Table 4 Main process parameters of SLM printing

Figure 2 M2 printer and vacuum heat treatment furnace

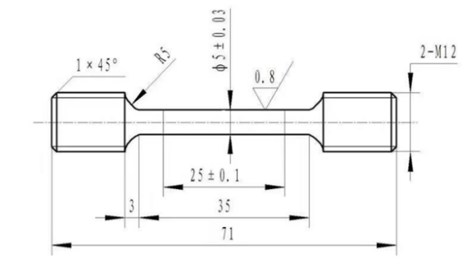

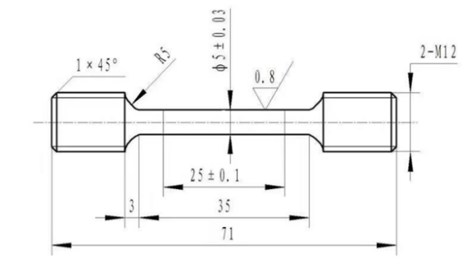

The TC4 powder was printed into a standard sample by direct molding, and its size is shown in Figure 3 below.

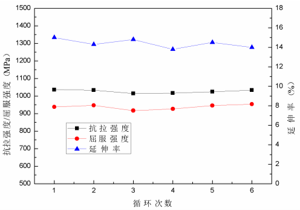

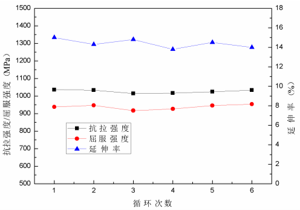

During the printing process of the standard sample, the powder was cycled for a total of 6 times for the cyclic printing test. As shown in Table 5 below, the tensile strength range of the 6-cycle printing samples is 22 MPa, and the yield strength range is 37 MPa. The difference between the strengths of each time is less than 5%, and there is no significant difference. The range of elongation is 1.2%, and the average value is 14.4%. It can be judged that there is no significant difference in the elongation of the printed samples after 6 cycles, as shown in Figure 4.

Therefore, during the 6-cycle printing process, there is no significant difference in the mechanical properties of the printed samples, that is, the TC4 powder can be printed cyclically for at least 6 times without obvious changes in the properties of the samples. The average tensile strength of the printed samples was 1027MPa, the average yield strength was 938MPa, and the average elongation was 14.4%.

Table 5 Performance parameters of cyclic printing samples

Application of TC4 powder selection laser printing

Some authoritative institutions have pointed out that aerospace is the most promising field for the R&D and industrial application of additive manufacturing technology. Machine level (engine, UAV, micro/nano satellite whole machine printing).

Since the 1980s, titanium alloys have been gradually used in oral restoration, dental implants, denture brackets and other fields. Today, as a research hotspot of biomedical implant materials, titanium alloys have been used in medical applications such as artificial joints, vascular stents, and orthopedic devices. As a commonly used biomedical titanium alloy, TC4 has been used clinically in my country. The traditional titanium alloy processing method is the casting method, which is complicated in operation, poor in precision, high in cost and pollutes the environment. At present, selective laser printing of titanium and titanium alloys is widely used in the production of crown and bridge restorations, dental implants, denture brackets, implant abutments and other dental fields, as well as artificial joint prostheses (such as hips, knees, ankles, shoulders, elbows, etc. ), osseointegration products, bone trauma products and spinal internal fixation systems and other orthopedic fields.

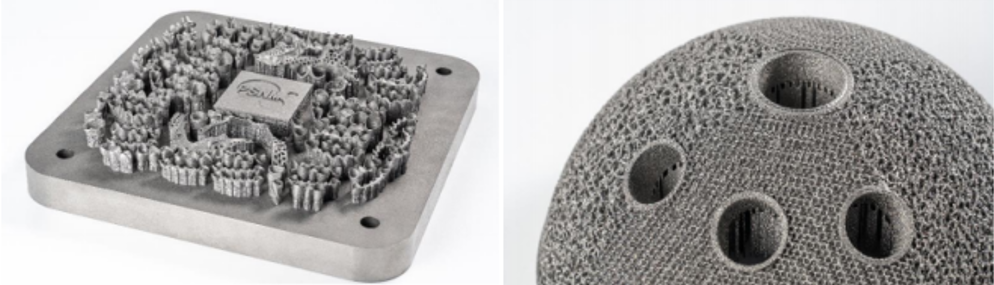

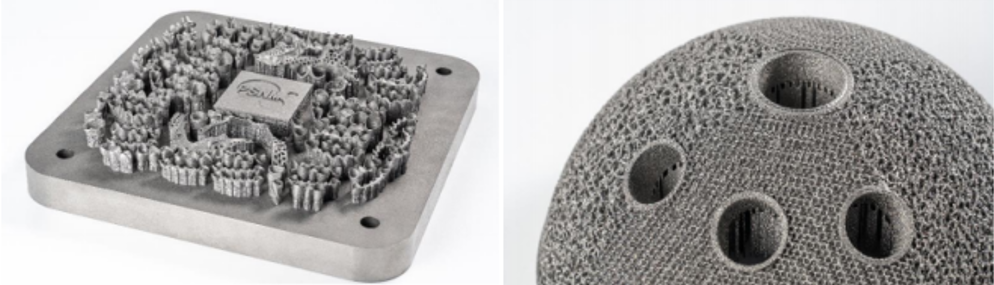

In the field of dentistry, SLM technology can carry out customized processing, can produce precise and personalized restorations, and has the best clinical application effect. This technology has been relatively mature in the production of dental stents, crowns and bridges. As shown in Figure 6 below:

In the field of orthopedics, porous titanium alloys have excellent corrosion resistance, biocompatibility, and mechanical properties that match human bone, making them an ideal orthopaedic replacement implant for the human body. The porous titanium material has a unique porous structure and rough inner and outer surfaces, which is conducive to the adhesion, proliferation and differentiation of osteoblasts, promotes the growth of new bone tissue, and is conducive to the formation of a whole between the implant and the bone. Figure 7 below shows the SLM-shaped TC4 acetabular cup.

Figure 6 Application of selective laser printing TC4 in the field of dentistry Figure 7 Application of selective laser printing TC4 in the field of orthopedics

Selective laser printing technology can imitate the specific complex design ability of natural structures, which is unmatched by traditional manufacturing methods. At the same time, it can realize customized services for patients and meet the needs of different groups of people for precision medicine.

CH

CH